Automobile Technology: CRDI (Common Rail Direct Injection):

CRDI (Common Rail Direct Injection)

CRDi stands for Common Rail

Direct Injection meaning, direct injection of the fuel into the

cylinders of a diesel engine via a single, common line, called the

common rail which is connected to all the fuel injectors.

Whereas ordinary diesel direct fuel-injection systems have to build up

pressure anew for each and every injection cycle, the new common rail

(line) engines maintain constant pressure regardless of the injection

sequence. This pressure then remains permanently available throughout

the fuel line. The engine's electronic timing regulates injection

pressure according to engine speed and load. The electronic control unit

(ECU) modifies injection pressure precisely and as needed, based on

data obtained from sensors on the cam and crankshafts. In other words,

compression and injection occur independently of each other. This

technique allows fuel to be injected as needed, saving fuel and lowering

emissions.

More accurately measured and timed mixture spray

in the combustion chamber significantly reducing unburned fuel gives

CRDi the potential to meet future emission guidelines such as Euro V.

CRDi engines are now being used in almost all Mercedes-Benz, Toyota,

Hyundai, Ford and many other diesel automobiles.

The common rail system

prototype was developed in the late 1960s by Robert Huber of Switzerland

and the technology further developed by Dr. Marco Ganser at the Swiss

Federal Institute of Technology in Zurich, later of Ganser-Hydromag AG

(est.1995) in Oberägeri. The first successful usage in a production

vehicle began in Japan by the mid-1990s. Modern common rail systems,

whilst working on the same principle, are governed by an engine control

unit (ECU) which opens each injector electronically rather than

mechanically. This was extensively prototyped in the 1990s with

collaboration between Magneti Marelli, Centro Ricerche Fiat and Elasis.

The first passenger car that used the common rail system was the 1997

model Alfa Romeo 156 2.4 JTD, and later on that same year Mercedes-Benz C

220 CDI.

Common rail engines have been used in marine and

locomotive applications for some time. The Cooper-Bessemer GN-8 (circa

1942) is an example of a hydraulically operated common rail diesel

engine, also known as a modified common rail. Vickers used common rail

systems in submarine engines circa 1916. Early engines had a pair of

timing cams, one for ahead running and one for astern. Later engines had

two injectors per cylinder, and the final series of constant-pressure

turbocharged engines were fitted with four injectors per cylinder. This

system was used for the injection of both diesel oil and heavy fuel oil

(600cSt heated to a temperature of approximately 130 °C). The common

rail system is suitable for all types of road cars with diesel engines,

ranging from city cars such as the Fiat Nuova Panda to executive cars

such as the Audi A6.

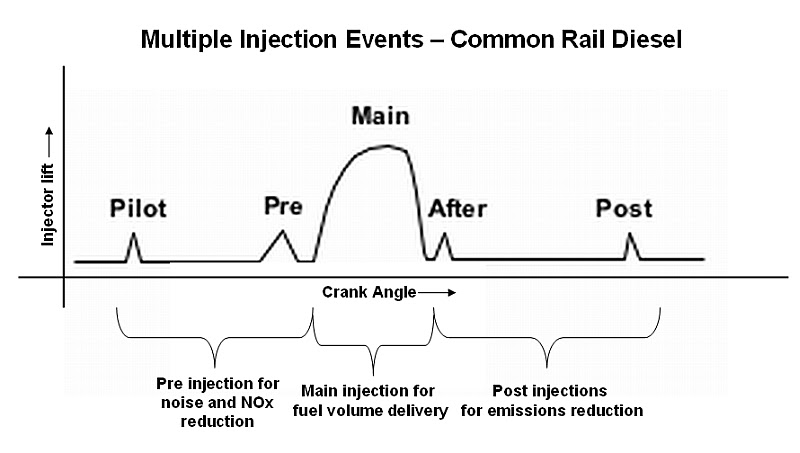

Solenoid or piezoelectric

valves make possible fine electronic control over the fuel injection

time and quantity, and the higher pressure that the common rail

technology makes available provides better fuel atomisation. In order to

lower engine noise, the engine's electronic control unit can inject a

small amount of diesel just before the main injection event ("pilot"

injection), thus reducing its explosiveness and vibration, as well as

optimizing injection timing and quantity for variations in fuel quality,

cold starting and so on. Some advanced common rail fuel systems perform

as many as five injections per stroke.

Common rail engines

require very short (< 10 second) or no heating-up time at all ,

dependent on ambient temperature, and produce lower engine noise and

emissions than older systems. Diesel engines have historically used

various forms of fuel injection. Two common types include the unit

injection system and the distributor/inline pump systems (See diesel

engine and unit injector for more information). While these older

systems provided accurate fuel quantity and injection timing control,

they were limited by several factors:

• They were cam driven, and

injection pressure was proportional to engine speed. This typically

meant that the highest injection pressure could only be achieved at the

highest engine speed and the maximum achievable injection pressure

decreased as engine speed decreased. This relationship is true with all

pumps, even those used on common rail systems; with the unit or

distributor systems, however, the injection pressure is tied to the

instantaneous pressure of a single pumping event with no accumulator,

and thus the relationship is more prominent and troublesome.

•

They were limited in the number and timing of injection events that

could be commanded during a single combustion event. While multiple

injection events are possible with these older systems, it is much more

difficult and costly to achieve.

• For the typical

distributor/inline system, the start of injection occurred at a

pre-determined pressure (often referred to as: pop pressure) and ended

at a pre-determined pressure. This characteristic resulted from "dummy"

injectors in the cylinder head which opened and closed at pressures

determined by the spring preload applied to the plunger in the injector.

Once the pressure in the injector reached a pre-determined level, the

plunger would lift and injection would start.

In common rail systems, a high-pressure pump stores a

reservoir of fuel at high pressure — up to and above 2,000 bars (psi).

The term "common rail" refers to the fact that all of the fuel injectors

are supplied by a common fuel rail which is nothing more than a

pressure accumulator where the fuel is stored at high pressure. This

accumulator supplies multiple fuel injectors with high-pressure fuel.

This simplifies the purpose of the high-pressure pump in that it only

has to maintain a commanded pressure at a target (either mechanically or

electronically controlled). The fuel injectors are typically

ECU-controlled. When the fuel injectors are electrically activated, a

hydraulic valve (consisting of a nozzle and plunger) is mechanically or

hydraulically opened and fuel is sprayed into the cylinders at the

desired pressure. Since the fuel pressure energy is stored remotely and

the injectors are electrically actuated, the injection pressure at the

start and end of injection is very near the pressure in the accumulator

(rail), thus producing a square injection rate. If the accumulator, pump

and plumbing are sized properly, the injection pressure and rate will

be the same for each of the multiple injection events.

Advantages

CRDi engines are advantageous in many ways. Cars fitted with this

new engine technology are believed to deliver 25% more power and torque

than the normal direct injection engine. It also offers superior pick

up, lower levels of noise and vibration, higher mileage, lower

emissions, lower fuel consumption, and improved performance.

In India, diesel is cheaper than petrol and this fact adds to the credibility of the common rail direct injection system.

Like all good things have a

negative side, this engine also have few disadvantages. The key

disadvantage of the CRDi engine is that it is costly than the

conventional engine. The list also includes high degree of engine

maintenance and costly spare parts. Also this technology can’t be

employed to ordinary engines.

The most common

applications of common rail engines are marine and locomotive

applications. Also, in the present day they are widely used in a variety

of car models ranging from city cars to premium executive cars.

Some of the Indian car manufacturers who have widely accepted the

use of common rail diesel engine in their respective car models are the

Hyundai Motors, Maruti Suzuki, Fiat, General Motors, Honda Motors, and

the Skoda. In the list of luxury car manufacturers, the Mercedes-Benz

and BMW have also adopted this advanced engine technology. All the car

manufacturers have given their own unique names to the common CRDi

engine system.

However, most of the car manufacturers have

started using the new engine concept and are appreciating the long term

benefits of the same. The technology that has revolutionized the diesel

engine market is now gaining prominence in the global car industry.

CRDi technology revolutionized diesel engines and also petrol engines (by introduction of GDI technology).

By introduction of CRDi a lot of advantages are obtained, some of

them are, more power is developed, increased fuel efficiency, reduced

noise, more stability, pollutants are reduced, particulates of exhaust

are reduced, exhaust gas recirculation is enhanced, precise injection

timing is obtained, pilot and post injection increase the combustion

quality, more pulverization of fuel is obtained, very high injection

pressure can be achieved, the powerful microcomputer make the whole

system more perfect, it doubles the torque at lower engine speeds. The

main disadvantage is that this technology increase the cost of the

engine. Also this technology can’t be employed to ordinary engines.

CRDI (Common Rail Direct Injection)

CRDi stands for Common Rail

Direct Injection meaning, direct injection of the fuel into the

cylinders of a diesel engine via a single, common line, called the

common rail which is connected to all the fuel injectors.

Whereas ordinary diesel direct fuel-injection systems have to build up

pressure anew for each and every injection cycle, the new common rail

(line) engines maintain constant pressure regardless of the injection

sequence. This pressure then remains permanently available throughout

the fuel line. The engine's electronic timing regulates injection

pressure according to engine speed and load. The electronic control unit

(ECU) modifies injection pressure precisely and as needed, based on

data obtained from sensors on the cam and crankshafts. In other words,

compression and injection occur independently of each other. This

technique allows fuel to be injected as needed, saving fuel and lowering

emissions.

More accurately measured and timed mixture spray

in the combustion chamber significantly reducing unburned fuel gives

CRDi the potential to meet future emission guidelines such as Euro V.

CRDi engines are now being used in almost all Mercedes-Benz, Toyota,

Hyundai, Ford and many other diesel automobiles.

History

The common rail system

prototype was developed in the late 1960s by Robert Huber of Switzerland

and the technology further developed by Dr. Marco Ganser at the Swiss

Federal Institute of Technology in Zurich, later of Ganser-Hydromag AG

(est.1995) in Oberägeri. The first successful usage in a production

vehicle began in Japan by the mid-1990s. Modern common rail systems,

whilst working on the same principle, are governed by an engine control

unit (ECU) which opens each injector electronically rather than

mechanically. This was extensively prototyped in the 1990s with

collaboration between Magneti Marelli, Centro Ricerche Fiat and Elasis.

The first passenger car that used the common rail system was the 1997

model Alfa Romeo 156 2.4 JTD, and later on that same year Mercedes-Benz C

220 CDI.

Common rail engines have been used in marine and

locomotive applications for some time. The Cooper-Bessemer GN-8 (circa

1942) is an example of a hydraulically operated common rail diesel

engine, also known as a modified common rail. Vickers used common rail

systems in submarine engines circa 1916. Early engines had a pair of

timing cams, one for ahead running and one for astern. Later engines had

two injectors per cylinder, and the final series of constant-pressure

turbocharged engines were fitted with four injectors per cylinder. This

system was used for the injection of both diesel oil and heavy fuel oil

(600cSt heated to a temperature of approximately 130 °C). The common

rail system is suitable for all types of road cars with diesel engines,

ranging from city cars such as the Fiat Nuova Panda to executive cars

such as the Audi A6.

Operating Principle

Solenoid or piezoelectric

valves make possible fine electronic control over the fuel injection

time and quantity, and the higher pressure that the common rail

technology makes available provides better fuel atomisation. In order to

lower engine noise, the engine's electronic control unit can inject a

small amount of diesel just before the main injection event ("pilot"

injection), thus reducing its explosiveness and vibration, as well as

optimizing injection timing and quantity for variations in fuel quality,

cold starting and so on. Some advanced common rail fuel systems perform

as many as five injections per stroke.

Common rail engines

require very short (< 10 second) or no heating-up time at all ,

dependent on ambient temperature, and produce lower engine noise and

emissions than older systems. Diesel engines have historically used

various forms of fuel injection. Two common types include the unit

injection system and the distributor/inline pump systems (See diesel

engine and unit injector for more information). While these older

systems provided accurate fuel quantity and injection timing control,

they were limited by several factors:

• They were cam driven, and

injection pressure was proportional to engine speed. This typically

meant that the highest injection pressure could only be achieved at the

highest engine speed and the maximum achievable injection pressure

decreased as engine speed decreased. This relationship is true with all

pumps, even those used on common rail systems; with the unit or

distributor systems, however, the injection pressure is tied to the

instantaneous pressure of a single pumping event with no accumulator,

and thus the relationship is more prominent and troublesome.

•

They were limited in the number and timing of injection events that

could be commanded during a single combustion event. While multiple

injection events are possible with these older systems, it is much more

difficult and costly to achieve.

• For the typical

distributor/inline system, the start of injection occurred at a

pre-determined pressure (often referred to as: pop pressure) and ended

at a pre-determined pressure. This characteristic resulted from "dummy"

injectors in the cylinder head which opened and closed at pressures

determined by the spring preload applied to the plunger in the injector.

Once the pressure in the injector reached a pre-determined level, the

plunger would lift and injection would start.

In common rail systems, a high-pressure pump stores a

reservoir of fuel at high pressure — up to and above 2,000 bars (psi).

The term "common rail" refers to the fact that all of the fuel injectors

are supplied by a common fuel rail which is nothing more than a

pressure accumulator where the fuel is stored at high pressure. This

accumulator supplies multiple fuel injectors with high-pressure fuel.

This simplifies the purpose of the high-pressure pump in that it only

has to maintain a commanded pressure at a target (either mechanically or

electronically controlled). The fuel injectors are typically

ECU-controlled. When the fuel injectors are electrically activated, a

hydraulic valve (consisting of a nozzle and plunger) is mechanically or

hydraulically opened and fuel is sprayed into the cylinders at the

desired pressure. Since the fuel pressure energy is stored remotely and

the injectors are electrically actuated, the injection pressure at the

start and end of injection is very near the pressure in the accumulator

(rail), thus producing a square injection rate. If the accumulator, pump

and plumbing are sized properly, the injection pressure and rate will

be the same for each of the multiple injection events.

Advantages & Disadvantages

Advantages

CRDi engines are advantageous in many ways. Cars fitted with this

new engine technology are believed to deliver 25% more power and torque

than the normal direct injection engine. It also offers superior pick

up, lower levels of noise and vibration, higher mileage, lower

emissions, lower fuel consumption, and improved performance.

In India, diesel is cheaper than petrol and this fact adds to the credibility of the common rail direct injection system.

Disadvantages

Like all good things have a

negative side, this engine also have few disadvantages. The key

disadvantage of the CRDi engine is that it is costly than the

conventional engine. The list also includes high degree of engine

maintenance and costly spare parts. Also this technology can’t be

employed to ordinary engines.

Applications

The most common

applications of common rail engines are marine and locomotive

applications. Also, in the present day they are widely used in a variety

of car models ranging from city cars to premium executive cars.

Some of the Indian car manufacturers who have widely accepted the

use of common rail diesel engine in their respective car models are the

Hyundai Motors, Maruti Suzuki, Fiat, General Motors, Honda Motors, and

the Skoda. In the list of luxury car manufacturers, the Mercedes-Benz

and BMW have also adopted this advanced engine technology. All the car

manufacturers have given their own unique names to the common CRDi

engine system.

However, most of the car manufacturers have

started using the new engine concept and are appreciating the long term

benefits of the same. The technology that has revolutionized the diesel

engine market is now gaining prominence in the global car industry.

CRDi technology revolutionized diesel engines and also petrol engines (by introduction of GDI technology).

By introduction of CRDi a lot of advantages are obtained, some of

them are, more power is developed, increased fuel efficiency, reduced

noise, more stability, pollutants are reduced, particulates of exhaust

are reduced, exhaust gas recirculation is enhanced, precise injection

timing is obtained, pilot and post injection increase the combustion

quality, more pulverization of fuel is obtained, very high injection

pressure can be achieved, the powerful microcomputer make the whole

system more perfect, it doubles the torque at lower engine speeds. The

main disadvantage is that this technology increase the cost of the

engine. Also this technology can’t be employed to ordinary engines.